Choosing not to use PFAS.

Industrial Cleaning Agent

VB1000 (PFAS-Free)

Water-Based High-Performance Cleaning Agent “VB1000”

A water-based, high-performance cleaning agent with no synthetic chemicals/surfactants, no organic solvents, no PFAS, and zero VOC emissions

High cleaning performance with outstanding safety

“VB1000” is a water-based high-performance cleaning agent made from over 99% water and less than 1% minerals. Because it contains no synthetic chemicals/surfactants, organic solvents, or PFAS, it delivers zero VOC (Volatile Organic Compounds) emissions and is fully compatible with VOC regulations. While being extremely safe for people and the environment, its strong cleaning power helps solve challenges across a wide range of industries.

VB1000 Ingredients

Three Key Features of VB1000

Test Results

Cleaning test results for water-soluble cutting oil and fine particles on various materials (metals and resins). “VB1000” demonstrates excellent cleaning performance across diverse materials. Effective removal was confirmed without compromising material characteristics.

High cleaning performance was also confirmed for graphite, which has been difficult to improve with conventional cleaners.

“VB1000” Cleaning Tests

Cleaning tests were conducted using water-soluble cutting oil and fine particles on each material.

For cutting oil: wipe test, spray test, and immersion test. For fine particles: ultrasonic cleaning test.

- S45C (Carbon Steel for Machine Structural Use): Water-Soluble Cutting Oil Cleaning Test Results

- S45C (Carbon Steel for Machine Structural Use): Fine Particle Cleaning Test Results

- SUS304 (Stainless Steel) / C1020 (Oxygen-Free Copper): Water-Soluble Cutting Oil Cleaning Test Results

- SUS304 (Stainless Steel) / C1020 (Oxygen-Free Copper): Fine Particle Cleaning Test Results

- PC (Polycarbonate): Water-Soluble Cutting Oil Cleaning Test Results

- PC (Polycarbonate): Fine Particle Cleaning Test Results

[Example] S45C (Carbon Steel for Machine Structural Use): Fine Particle Cleaning Test Results

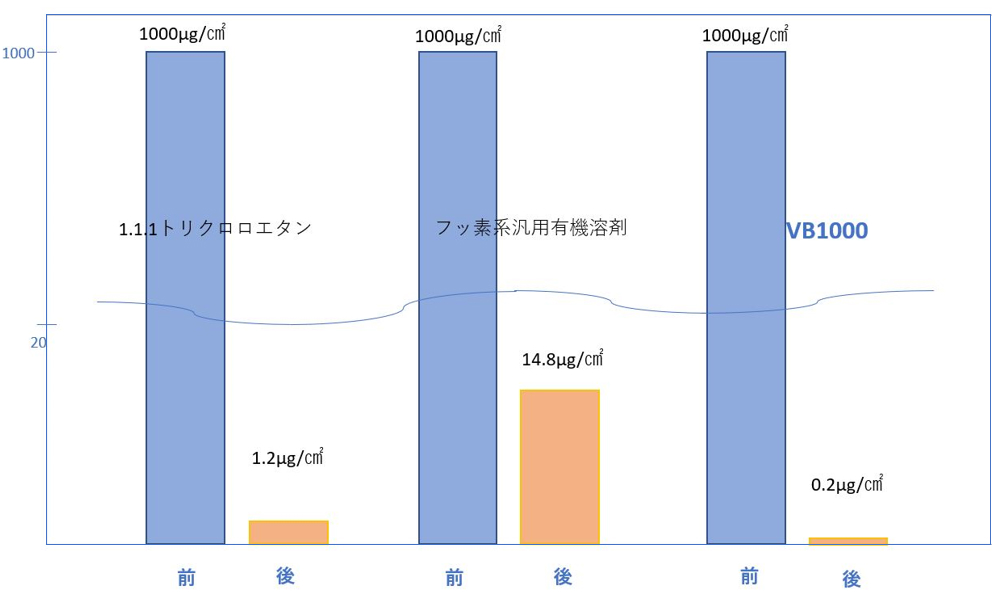

VB1000 Cleaning Performance Comparison

Cleaning Effect When Used as an Ultrasonic Cleaning Agent

[Test Method] A metal surface polished with a metal polishing compound was ultrasonically cleaned for 10 minutes in each sample solution, and the surface residue was measured using a microbalance.

High Safety

“VB1000” delivers high levels of “Safety” and “Peace of Mind.”

Safety of VB1000

VB1000 is extremely safe because it is composed only of water and minerals.

A range of safety tests are conducted at the raw-material stage.

For hazard information, please refer to SDS Section 11 (Toxicological Information).

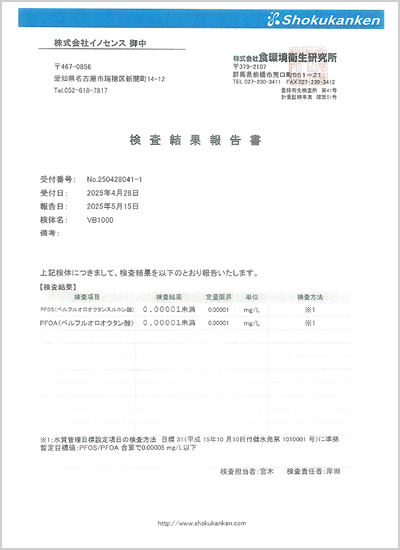

VB1000 is a water-based high-performance cleaning agent made from water and trace minerals, and is exceptionally gentle for both people and the environment. Because it contains no harmful chemicals—such as surfactants, organic solvents, PFAS, or heavy metals—it produces zero VOC (volatile organic compound) emissions and fully complies with VOC regulations. It can significantly reduce the safety concerns associated with conventional cleaners.

- Significant reduction of occupational accident risk and environmental burden

- Simplified compliance with laws and regulations

It significantly simplifies corporate compliance and risk management, delivering substantial benefits for adopting companies. For detailed safety data and handling information, please refer to the Safety Data Sheet (SDS).

Applicable Regulations for VB1000

Whether it falls under laws requiring SDS provision for chemicals

- Not applicable: Industrial Safety and Health Act (not a notifiable substance)

- Not applicable: Poisonous and Deleterious Substances Control Act

- Not applicable: PRTR law

Primary domestic laws applicable: No major applicable regulations

Benefits of Introducing “VB1000”(Concrete Benefits You Gain)

Introducing VB1000 goes beyond improving a cleaning process—it brings multi-faceted business benefits and innovation.

Dramatically improved safety

Dramatically improved safety

Eliminates fire risk

Eliminates fire risk

Simplifies storage and management

Simplifies storage and management

Reduces wastewater treatment burden

Reduces wastewater treatment burden

Optimizes global transportation

Optimizes global transportation

Reduces PPE burden

Reduces PPE burden

Reduces equipment investment and maintenance costs

Reduces equipment investment and maintenance costs

Minimal impact on materials

Minimal impact on materials